O-ring Extrusion

Pressure applied evenly to both sides of a seal normally has no effect on sealing performance. When a pressure difference is anticipated, elastomer selection must also consider differential pressure resistance. High differential pressures will cause improperly specified O-rings to extrude, resulting in seal damage and eventually failure.

Standard O-ring groove and gap dimensions cited in MIL-G-5514 and AS4873 generally provide adequate sealing for differential pressures to 1500 psi for all elastomers. Substantial improvement in extrusion resistance is attainable by 1) using harder O-rings, 2) decreasing the diametral clearance, or 3) using contoured hard rubber or plastic back-up rings. O-rings with high modulus and hardness are better able to resist extrusion. The higher the modulus of a material, the greater the force required to stretch it. Similarly, the harder the material, the greater its resistance is to indentation.

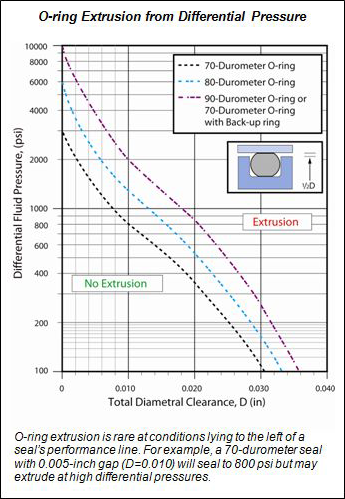

The following graph indicates conditions that result in O-ring extrusion with and without back-up rings.